Sheet metal laser cutting is a thermal cutting process used in metal fabrication wherein a laser beam is directed onto a workpiece to melt, cut, or vaporize it. How exactly does this metal laser cutting process work? In this blog, Solera Metal Fabrication, a major custom metal fabricator in Brampton, Ontario, explores the process of laser sheet metal cutting in detail.

How Does Sheet Metal Laser Cutting Work?

Design Phase

Since this is a CNC-powered process, CAD or CAM software is used to finalize the desired dimensions and shape of the cut to be made. Once the right dimensions and tolerances are finalized, the operator can proceed to the next step.

Setup

Depending on the pattern, dimensions, and tolerance desired from the part, various parameters of the laser cutting machine, such as laser power, speed, rate of flow of assist gas, and more, are determined. This is essential as it will directly determine the accuracy and precision of the cut. Assist gas, on the other hand, is vital in sheet metal laser cutting as it protects the processing head from vapours and splashes during laser cutting.

Cutting Process

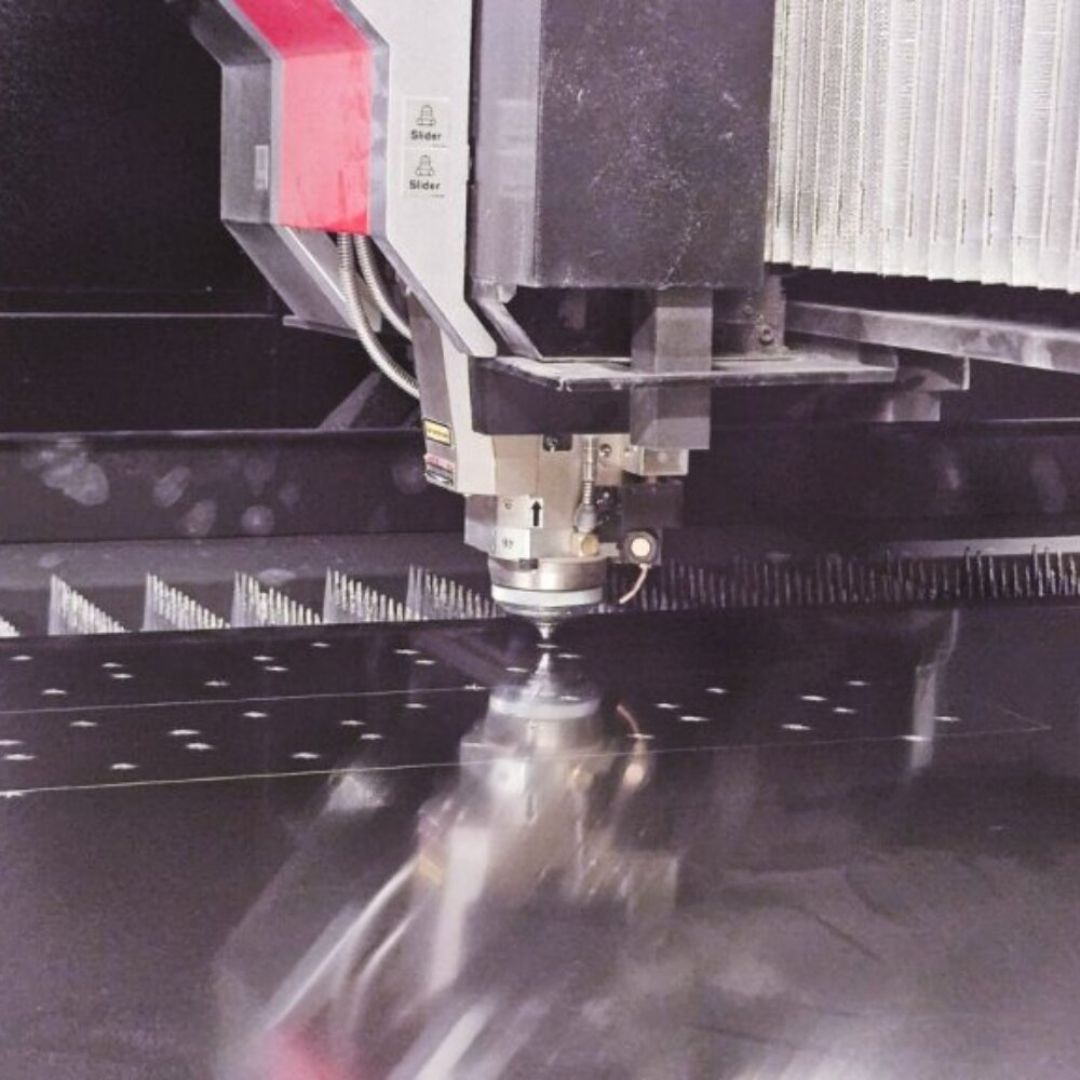

The laser beam is focused on the workpiece at a desired speed and intensity. This results in the melting or vaporizing of part of the workpiece, thereby making a cut. Depending on the thickness of the workpiece, the cutting process may be repeated a few times.

Part Removal

The molten or vaporized part is then blown away or removed by means of the assist gas, which also prevents the formation of burrs and other small residues that may require an extra process.

Conclusion

In closing, laser sheet metal cutting is an intricate CNC-controlled process that requires design planning, setting parameters, cutting, and safe removal of parts for the best results.

Want to learn more about this metal-cutting process? Solera Metal Fabrication is here to help. As one of the reputed custom metal fabricators in Brampton, Ontario, we offer expert metal cutting services for carbon steel, aluminum, stainless steel, and other types of special alloys. For more details, contact us at 905-457-4777 today.

FAQs:

What are the most prominent laser metal cutting processes?

The most common laser metal cutting processes include fusion cutting, sublimation cutting, and flame cutting.

What are the benefits of sheet metal laser cutting?

The major benefits of sheet metal laser cutting include high precision, accuracy, material compatibility, versatility, and low energy consumption.